Indicators on Motorcycle Parts New Zealand Specialists You Need To Know

Table of ContentsThe Best Guide To Motorcycle Parts New Zealand SpecialistsAll about Motorcycle Parts New Zealand SpecialistsIndicators on Motorcycle Parts New Zealand Specialists You Need To KnowFacts About Motorcycle Parts New Zealand Specialists Revealed7 Simple Techniques For Motorcycle Parts New Zealand SpecialistsGetting The Motorcycle Parts New Zealand Specialists To WorkAn Unbiased View of Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?

So, connect to among our experts today.CNC machining innovation is quickly ending up being the prime focus of various production procedures around the globe as a straight outcome of its numerous benefits over various other approaches. Furthermore, the industries that manufacture motorcycles have actually jumped on board with this fad. One of the most cutting-edge companies are currently developing their engine parts and wheels using machining techniques initially established for motorbike parts.

You might be questioning why we use. Currently that we have your interest let us explain the rationale behind this modern-day advancement in the motorbike production sector.

The 45-Second Trick For Motorcycle Parts New Zealand Specialists

In addition, you have full control over the appearance of the parts, even down to the minute details. Sometimes, motorcyclists may make a decision to beautify their trip by setting up aftermarket components or customizing the bike's makeover. Once more, computer numerical control (CNC) machining is the most sensible technique. Upgrades may be of any form and style you desire.

Getting The Motorcycle Parts New Zealand Specialists To Work

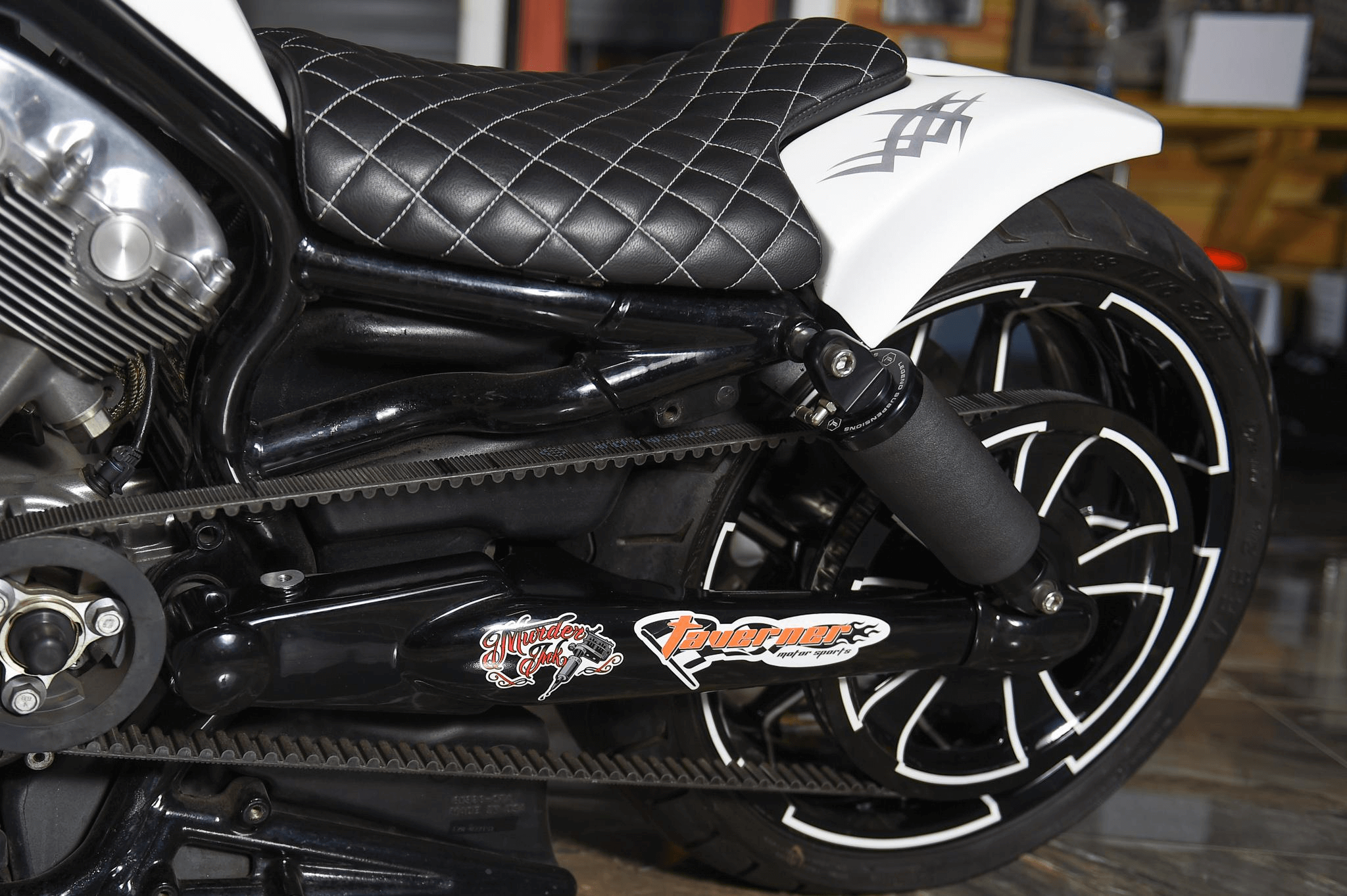

CNC machining might be utilized to make mostly all of a motorcycle's steel and plastic parts. To proceed, we'll discuss several machined parts for motorcycles. Unlike those on cars, wheels on bikes have a tendency to be a lot more evident. Therefore, the bike's appearances might be enhanced with the proper modification of these wheels.

When customizing the wheels, the disks are where the focus must be. The majority of them are made out of light weight aluminum. Light weight aluminum alloys are well-known for the exceptional machining capabilities that they have. Milling treatments are used to get the preferred level of wheel personalization. Another aspect of the motorbike that may be individualized is the tires.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

When it concerns a car (or a motorbike), the most important component is the engine. Numerous individuals mention it as the "heart" of the vehicle. On the other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be intricate and need layouts with a high degree of accuracy.

Lighting is an additional complicated element of personalization. Usage only high-quality items, nonetheless, since these lights are critical for the safety of motorcyclists and other drivers or individuals when driving, specifically at night. Motorbike fronts lights have three almosts all: the light bulb, or source of light, the lens, and the housing. Particularly, we tailor the lens and the housing.

Milling processes with a perfect coating would certainly result in the lenses having a reflective quality that is comparable to that of a mirror. The cover, on the various other hand, is not made up of vulnerable products; rather, it is created out of difficult polymers that can be machined into even more detailed patterns.

An Unbiased View of Motorcycle Parts New Zealand Specialists

Motorbike suppliers typically cast these parts, but only reference for the production of bespoke parts. Machining on 5 axes in today's globe is the ways by which any type of design form may be realized.

Choose Runsom for your tailored bike components! We have the capacity to produce challenging and stylish parts making your motorcycle matchless.

Right here are a couple of examples of steels often used in motorbike component machining. Light weight aluminum is the main material utilized by companies specializing in producing custom-made motorcycle elements to produce many of these parts - Motorcycle Parts New Zealand more helpful hints Specialists.

Zinc refers to another steel that is really light in weight and has fantastic machining qualities because of its high mechanical stamina. This material may be formed right into almost any kind of form and maintains its measurements well. Also mission-critical components that require a high level of precision might gain from their usage.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered

One more steel that sees hefty use in the production of CNC-customized components is magnesium. It is amongst the lightest steels that are now accessible and has exceptional machinability attributes and toughness appropriate with its reduced weight. Among the drawbacks of magnesium is that its dirt might easily capture fire.

Their most typical use in producing various motorbike parts is bolts, such as screws and bolts. Their low sensitivity to oxidation and rust makes them perfect for this usage.

Indicators on Motorcycle Parts New Zealand Specialists You Need To Know

It seems that CNC transforming and milling are the foundational procedures. Alternative methods exist, such as exploration. Allow's explore a number of these machining methods detailed. The CNC turning method is considered a subtractive manufacturing method. Furthermore, it needs keeping bars of material, frequently plastic or steel, ready and after that turning a reducing tool to eliminate areas of the material as the material is turned.

These methods are equally crucial and produce components with high precision and regular top quality. The procedures assist improve the overall quality of the machined motorbike components.

Motorcycle Parts New Zealand Specialists for Beginners